Anodizing

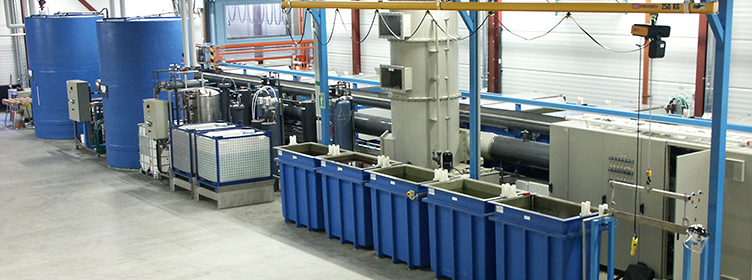

Anodizing is a method to surface treat (oxidize) the surface of aluminum parts. The method is applicable to hanging goods, meaning parts that are fixed individually. To the traditional anodizing applies different types of coloring through which the aluminum part gets an attractive look, as well as an increased wear resistance and a corrosion resistant surface. After coloring, the part is dipped in a post-sealing bath. Hot (98 deg. C) post-sealing baths are most common. Using the PROGAVENT™-system for the plant gives an extra advantage both to work environment and to the economy. One anodizing method is hard-anodizing. As the description tells, a hard and wear resistant surface is added to the part when using this method. Hard-anodizing is made with an anodizing process working at below-zero temperatures. PROGATEC has good competence in all kinds of surface treatment of aluminum, and can probably offer the most competitive solution to Your needs.