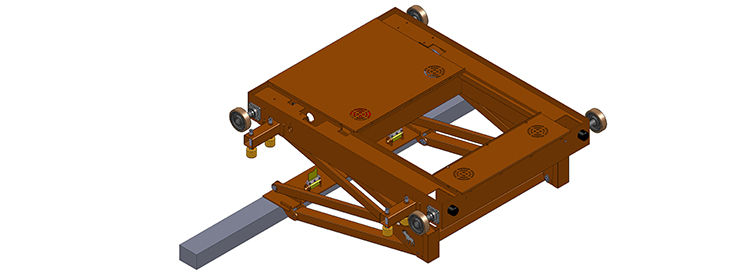

The ProgaLift TF is our transporter run on rails in level with the tub edge or just over it. It is characterized by a very robust steel construction that is easy to serve. We choose the ProgaLift TF when the plant is built with the PROGAVENT™ system, since the housing that seizes bath emissions lets itself be integrated with the basic transporter construction. As a standard the ProgaLift TF is made for goods up to 3 tonnes.

The ProgaLift D is a transporter run on rails that are assembled to rafters or to a stand-alone portal construction. “D” means that the parallelogram design that the lifting arrangement is built around forms a D at an intermediate position. This type of transporter is chosen first-hand if making a device where you wish to avoid fixed guides for the air construction. It is also a first-hand choice for basket centrifuge sections in drum-galvanization when our design for basket tilting and rotation is used for simple assembly on the ProgaLift D.

We have designed the ProgaLift D to be run on top of the rail profile. Other, relatively similar designs, are run in the middle of for example a U-profile. This is a difference that makes the ProgaLift D easier to service and repair. As a standard, the ProgaLift D is made for cargo weights between 300 and 1000 kg.

The PROGATEC transporter is positioned by absolute encoders and is run exclusively by frequency converters. A soft acceleration and retardation is secured.

Apart from this, there is also special transporters for our centrifuge hot-dip galvanizing plants.