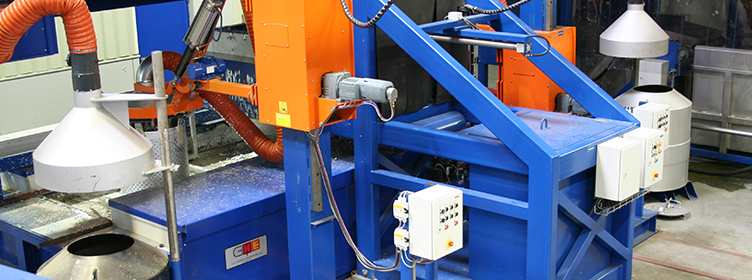

Automatic Hot-dip galvanizing, Type A

The plant is designed for an automatic flow of goods through the entire hot-dip galvanizing process, including pre-treatment. The automatic drive ensures top quality with even and repeatable results. The process control allows galvanizing with individual adaptation for different types of goods. The centrifuge hangs over the zinc pot. It has an open bottom, making the centrifuged zinc fall directly back into the zinc pot. The production does not have to stop to clean the centrifuge, thus providing high production volumes. A ceramic hot-zinc pot is a valuable choice, since it allows zinc treatment at 560 ºC.

This provides the best zinc quality for complex details. A ceramic pot also has the advantage of smaller zinc expenditure as well as not having to change zinc pots. Also, a ceramic pot allows a higher content of Aluminum. The baskets circle through the plant without interruptions, letting them remain hot. New goods is pre-heated by the hot basket, providing better drive economy. The standard available basket designs are diameter 500 mm, height 400-500 mm, in the materials stainless steel (SS2333, 1.4301), acidproof stainless steel (SS2348, 1.4404) or Armco Steel (pot steel).

Maximum weight for goods in the basket is 70 kg.